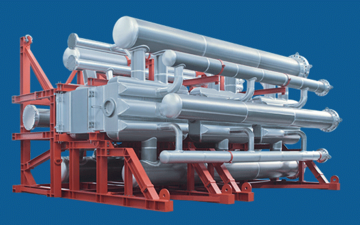

Coldboxes, packaged units and cryogenic columns

World expert in cryogenic process plant design, we are a technology leader in the engineering of packaged units, coldboxes and columns.

The self-supporting steel compartment comprises a number of components including:

-

Columns

-

Plate-fin heat exchangers

-

Pressure vessels

-

Separators

-

Interconnecting piping

-

Instrument lines for temperature and pressure measurements

-

Pressure difference and level indicators

-

Wall penetrations

-

Valves

Downloads